Component Testing for

R&D and System-Level Validation

Your component doesn’t operate in isolation—

neither should your test strategy.

we specialize in performance

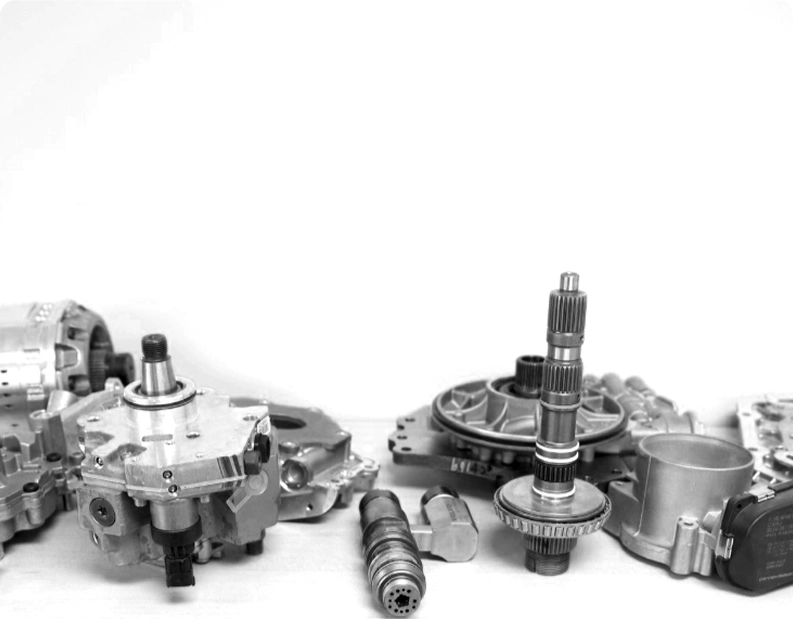

At ATA, we specialize in performance, durability, and integration testing for critical electro-mechanical components used in powertrain, thermal management, and electrified systems. From pumps and heat exchangers to valves and nozzles, we help R&D teams validate not just if a part works—but how it performs under real-world conditions.

Whether you’re supporting a design iteration or benchmarking competitive solutions, our test environments replicate the loads, cycles, and interactions your components will face once deployed.

What We Test

of platforms, including:

- Mechanical or electric, fixed or variable displacement, engine or transmission oil pumps

- Mechanical or electric water/coolant pumps

- Heat exchangers or oil coolers

- Solenoid oil or coolant valves

- Nozzles and injectors

- Other mechanical or hydraulic subassemblies (e.g. wheel hub bearings, battery stack, electric power steering unit, etc.)

Simulated Conditions We Replicate

Our systems are built to reproduce real-world scenarios with high

fidelity including but not limited to:

Thermal

cycling

Test loops with programmable ramp/hold profiles

Pressure and

flow control

Dynamic load simulation with high-resolution closed-loop control

Mechanical

loading

Torque, axial/radial force, and duty cycle simulation

Environmental exposure

Endurance under contaminated fluids, cavitation, dry-run, or air entrainment

Engineering Deliverables

- High-resolution raw data synchronized across all parameters

- Custom test scripts based on your spec or jointly defined targets

- Time-based, cycle-based, or condition-based test logic

- Support framing results for internal validation or customer submission