PROTOTYPING

COMPONENT SELECTION

DRAWINGS

MACHINING

ASSEMBLY

DFM

MATERIALS SPECIFICATION

DFMEA/PFMEA

WORK INSTRUCTIONS

TEST PROCEDURES

COMPONENT SELECTION

DRAWINGS

MACHINING

ASSEMBLY

MATERIALS SPECIFICATION

DFMEA/PFMEA

WORK INSTRUCTIONS

TEST PROCEDURES

“Update on ATA Lab testing progress with the product... Must say this is one of the better experiences with a test lab to date in terms of keeping us updated, hitting date milestones and capabilities”

“I worked with ATA for years. The customer service received from their staff is the best. Everyone there is very polite and patient when providing help, whether on the phone (which is instant), a remote connection through a computer, or an on-site visit.”

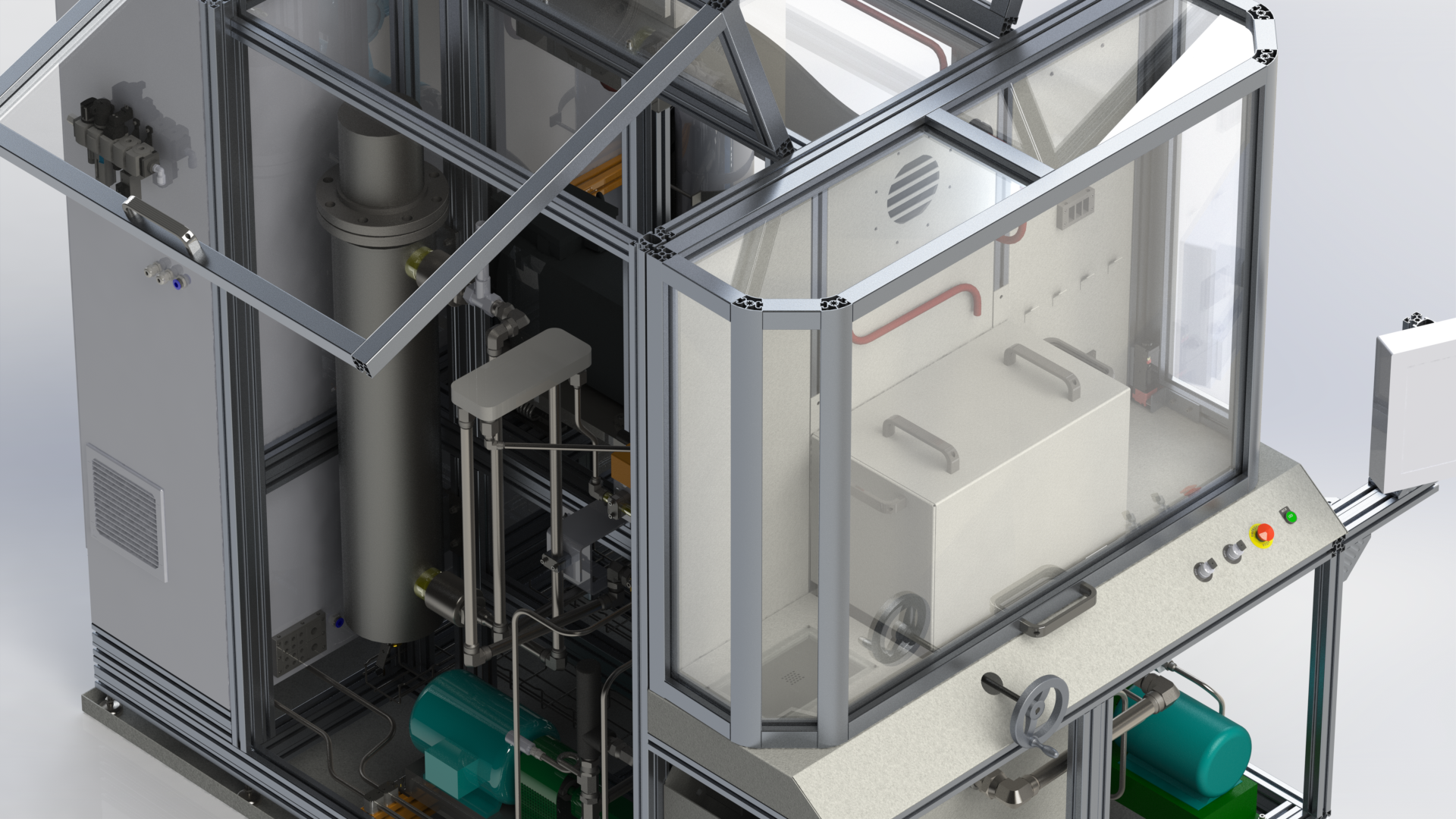

ATA is motivated to provide creative solutions where technical uncertainty exists, especially within the realm of fluid mechanics and electromechanical devices. We simplify the process of accurately quantifying physical phenomena, like pressure, flow, speed, torque, force, voltage, current and more. We believe quantification leads to understanding, which ultimately yields a better product.

Since 2006, we have:

Provided test systems and services for design and production use in the automotive, aerospace and medical device industries

Designed, prototyped and manufactured pneumatic modules for ventilators

Developed aeration measurement technology and control techniques used in automotive, off-highway, defence and industrial applications

Engineered temperature conditioning technology that can be applied to develop better thermal management systems for batteries, electric vehicles, heavy equipment and more

ATA wishes to empower engineers worldwide with a wide array of proven building blocks to rapidly prototype, test and manufacture new products.

ATA strives to provide the quickest time to market for new products within the fluid mechanics realm.

A proven platform of modules, each made up of components and processes combined to serve a particular function in a fluid device. With nearly 800 modules to choose from (complete with models, drawings, instructions and test requirements), deploying Section ID as part of a new product significantly reduces time-to-market.

Modules are pre-designed

Short lead times

Guidance for module selection

TURN-KEY

Application-specific

Meets relevant standards

Includes hardware, software and processes

Rigorous performance and durability tests

Robust and easy-to-scale

Used in products and systems globally