Whether it is your first time designing a vane pump or the tenth time, it is good to know the most common pump element design materials, component dimensions, and best practices.

Whether it is your first time designing a vane pump or the tenth time, it is good to know the most common pump element design materials, component dimensions, and best practices.

We sat down with OEMs, seasoned pump design release engineers and validation technicians. We wanted to understand the most frequent variable displacement vane pump failures and how someone developing these pumps could avoid them.

Out of our research came a detailed eBook discussing the problems, design tips, and standard validation procedures for each. In our blog post today, we will be breaking down some of the more crucial design tips for variable displacement vane pumps.

Different Drive Configurations & Their Impact

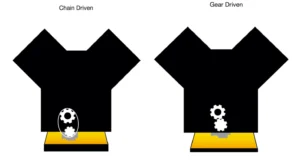

There are a few different configurations that can be used to drive the pump, each resulting in a different effect on its performance. At a high level, the drive types fall into two categories – direct-drive and indirect drive.

There are a few different configurations that can be used to drive the pump, each resulting in a different effect on its performance. At a high level, the drive types fall into two categories – direct-drive and indirect drive.

In a direct-drive configuration the pump is usually mounted on the inside of the front engine block cover and driven by the crankshaft. The indirect driven pump is mounted at the bottom of the engine immersed in the oil in the sump. Various indirect drives types include chain and sprocket, spur gear, helical gear driven and piggyback on the balancer drive shaft.

Due to the varying levels of rigidity when coupling to the pump drive shaft, it can transmit a corresponding engine pulsation profile (with regards to intensity). For example, indirect drives such as chain-drive will transmit the pulsation profile to a lesser degree as the chain acts as a dampener between the engine crankshaft and pump. Where an indirect drive (ie. chain or gear driven) finds its advantages is in the added flexibility of the application, such as mounting configuration. Additionally, this allows for adjustment of the speed ratio between the crankshaft and the pump shaft. The disadvantage of using an indirect drive is that it introduces a higher cost and level of complexity by requiring more components. This option also ends up taking more space.

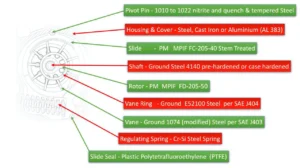

Materials used

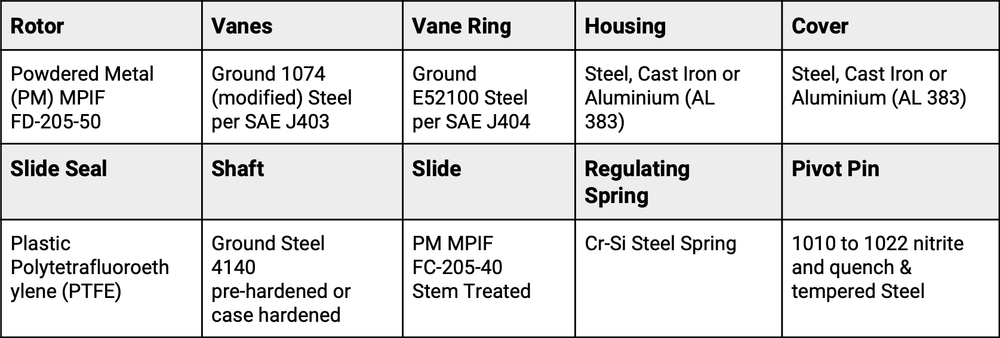

Everything we have already discussed is crucial in designing a variable displacement oil pump, but the materials used can quite literally make or ‘break’ the project. In some areas, it may be justified to save cost with plastic components, whereas in other areas it may be crucial to use stiff and durable ground steel. For example, vanes are typically made from steam-treated powdered steel, as this has proven to be more resistant to wear. For bushings, you’ll want to make sure the hydrostatic oil film thickness is higher than the surface finishes on components rubbing against each other.

In our eBook, we dive into each of the component failures often found within variable displacement vane pumps, give specific design tips for each, and dive into why the materials listed are typically used.