3D Printed Powertrain Components

Today, we are constantly striving to make our businesses more cost efficient. In automotive, this is especially true in the context of research and development. The prototyping stage can lead to wasted materials, space and capital for inventory or time awaiting the delivery of specific components.

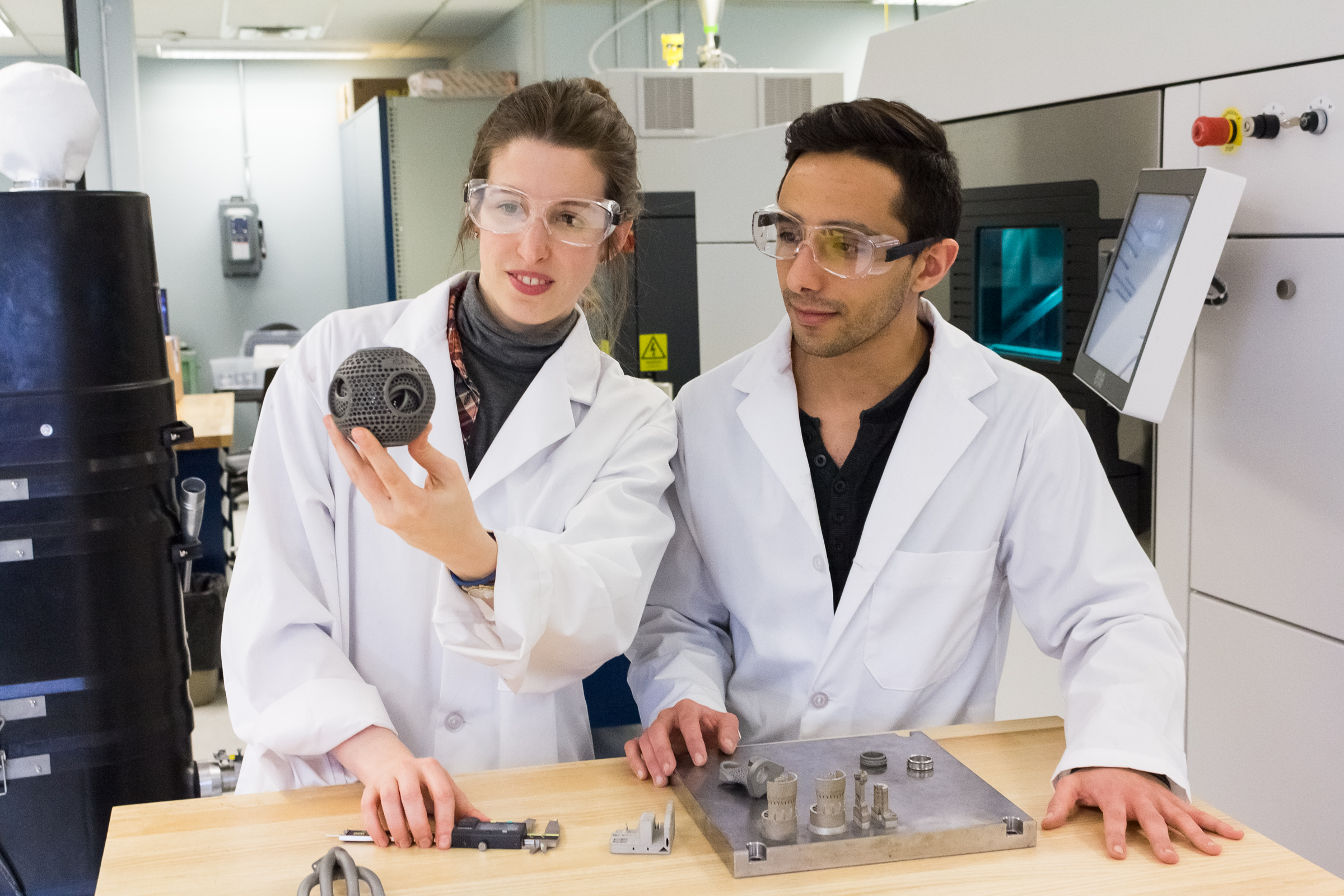

Throughout the next several months, ATA will be offering our industry expertise in collaboration with the University of Waterloo (UW) MSAM (Multi-Scale Additive Manufacturing Laboratory). Together, we hope to understand the plausibility for 3D-printed oil pump housings that meet industry standards and answering the questions that currently revolve around the durability and performance of 3D-printed automotive components.

We started with two questions: Are automotive companies researching and testing additive manufacturing? If so, then what steps are they taking to implement this into their projects going forward? UW's Lisa Brock informed of the several industry-leading companies that are currently conducting case studies and even implementing additive manufacturing to their portfolio. "GE Aviation has printed a lightweight turboprop engine using additive manufacturing, consolidating 855 parts to only a dozen components", says Lisa. This means the new bill of materials is just over 1% of what it was before 3D-printing. In fact, GE Aviation currently mass produces a 3D printed nozzle tip for use in their LEAP jet engine.

Additive manufacturing has extended to automotive. According to Lisa, "Companies including BMW, GM, Ford, Honda, Hyundai, Jaguar, Volkswagen, Mercedes and various motorsport companies have been known to use additive manufacturing for a variety of applications". Lisa referenced components like "exhaust manifolds, pump components, molds and cores". General Motors has published videos demonstrating how they are using additive manufacturing within their pre-production process. GM is currently operating 16+ SLA and SLS machines in order to produce over 20,000 printed parts yearly. Another example is how Honda's racing department managed to reduce their time of testing for an extremely time sensitive project by four weeks using a 3D printer (ProJet 3000 CPX).

Next, we wanted to know what the largest benefits were going to be for late adopters when/if they choose to introduce additive manufacturing to their R&D and/or production process. Lisa assured us that the integration of additive manufacturing can provide design freedoms that traditional manufacturing methods cannot provide. "This can include the ability to pivot from concept to prototype quickly and easily, as the shorter lead time results in accelerated design cycles", says Lisa. She continued by stating that "additive manufacturing is well-suited for the manufacturing of internal features, passageways, and organic or complex geometries, therefore enabling specialized designs with reduced wight and potentially enhanced performance". Like referenced before, the additive manufacturing of a component may also result in less waste then the traditional manufacturing methods. Lisa says that this is due to the part being built up layer-by-layer rather than having someone machine it out of a larger block of material (which is also less cost efficient).

3D printing was first introduced back in 1983 for plastics. It wasn't until the lates 80's and early 90's that we started to see the technologies for printing metals. Why is the appeal larger today than it was 30 years ago? According to Lisa, "in more recent years, additive manufacturing has been viewed as a mature enough technology for the industrial uses beyond just research and development". So, even though there is still a lot of room for growth in terms of machine development, material capabilities, and process optimization, modern 3D printing technologies are thought to be able to meet industrial manufacturing standards. "As a result, two questions emerge." Lisa asks, "What can be done through additive manufacturing, and what should be done?" This question arises because the feasibility of the process and overall advancement of the product needs to be prioritized.

What about the durability of 3D-printed components? We are interested in a familiar example: the oil and water pump housing. Pumps can undergo extreme temperature fluctuations and can be operating at full capacity for hours on end. This is especially true with the introduction of electric vehicles, where the duty cycles are expected to go up. These are precisely the answers that ATA and UW hope to uncover.

What will the outcome be? Is it feasible to introduce additive manufacturing into the pump R&D space? Can we utilize 3D-printing within a production flow? These will all be answers we look to answer in the coming months, so stay tuned.