Pump Testing Methodologies

Our Product Solution

A test platform devoted to thoroughly capturing and understanding the failure modes of mechanical oil pumps ensures the dependability your customers value most.

Whether developing a new hydraulic pump design that has to closely match predefined specifications, or verifying the functionality of a production unit, an accurate and reliable test system is needed to confirm the functional parameters of those pumps. No matter if you are dealing with fixed or variable displacement pumps, or having to test in conformance with specific SAE or ISO standards, or custom OEM specifications, ATA engineers can help you by delivering the right tool for your needs.

ATA can provide customized test solutions for the following kinds of pumps:

engine oil pump

engine water pump

automatic transmission oil pump

power steering pump

brake vacuum pump

air injection pump

ABS pump

supercharger compressor

rotary gear pump

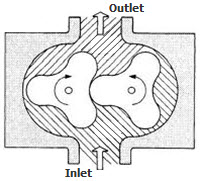

external gear

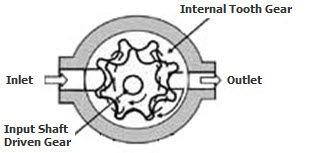

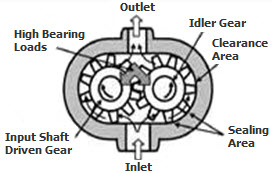

internal gear (Gerotor)

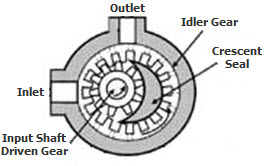

internal gear with crescent

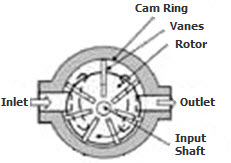

rotary vane pump

centrifugal impeller pump

lobe pump

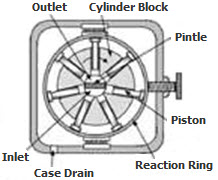

piston pump

ATA Design Process

OUTSOURCE YOUR COMPONENT TESTING TO US!

Whether you are seeking specific testing expertise for a new product, or looking for additional test capacity, we are ready to support you.

ATA Lab™ consists of our latest systems, standards and technology. Leading test methods include aeration testing and durability & performance testing strategies.

Click here to learn more.

In order to develop an optimal design for an application, or verify a production line part, ATA engineers must be able to confirm many, if not all, of the numerous pump parameters listed below:

proper pump assembly

required preconditioning

pressure & flow capacity

inlet pressure control

pressure relief valve

pressure & flow compensator

pulsed-flow behavior

pressure stability

seal leakage

maximum temperature

thermal shock

erosion resistance

cavitation

aeration testing

cold testing

acoustic noise

axial & radial load

delivery characteristics

power input

volumetric efficiency

mechanical efficiency

overall pump efficiency

vibration level

contamination testing

durability & endurance

After collecting the appropriate data, analysis and interpretation of this data is needed to come up with definite and meaningful test conclusions. This can include time-domain graphing of parameters such as speed or flow rate, frequency-domain analysis of emitted noise, order analysis of pressure pulsations, and many others. Stay tuned for further case studies showcasing some of the work ATA has done with leading companies in the pump industry, in helping them gather vital test data.

A test platform devoted to thoroughly capturing and understanding the failure modes of mechanical oil pumps ensures the dependability your customers value most.

Learn more about our mechanical oil pump test system.