Dual Head Fuel Injector Performance Test

After production and before products go into field usage, it is necessary to conduct complete end-of-line performance testing. In the case of their advanced dual-head fuel injectors, our client recognized the need to fully evaluate all production components within their injectors, and to subject these components to rigorous test conditions.

Custom testing solutions can apply for most fuel injectors including:

- Gas compression ignition

- Gas spark ignition

- Petrol

- Diesel

- Hybrid (liquid/gas)

- Other alternative fuels

In this application, the client manufactured leading clean-burning alternative fuel injectors.

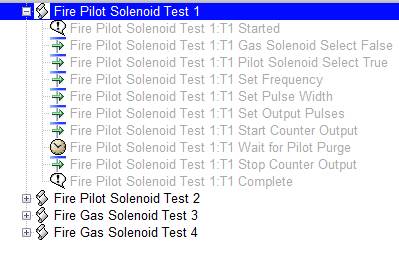

Our advanced testing software allowed for fully automated custom test sequences.

Primary performance test variables included:

- frequency

- pressure

- flow

- temperature

ATA engineers integrated injector driver boxes with external power supplies and automated component clamping and unclamping for quick test part interchanges. The test system allowed our client to customize test specifications for validation of their existing injector models, as well as for development of new prototypes. Test results are then easily exported into existing data tracking and analysis applications.

Despite customization, turnaround time and test system delivery can be done quickly to help get products fine-tuned and into the marketplace.